condom manufacturer’s new trend

The condom production’s competition is fierce too although there isn’t so many factories in the world. The production line’s huge capacity is easy make the market fully, so each factory has to study their own position in the market, such as new material, thin in thickness, the texture of the surface, and bulk production make average cost lower, full range …

Establishment of Condom Manufacturing Plant in Africa

Producing condoms locally to meet local demand by creating a sustainable healthcare industry. Project Description: Setting up an efficient and innovative manufacturing plant of condoms, as well as related marketing capacities to private & social marketing entities within Eastern Africa & internationally- location: data suggests Uganda or Tanzania. The plant will be the first of its kind in Africa and …

India GST make condom manufacturing more expensive

The Goods and Services Tas(GST) regime has made manufacturing condoms in India more expensive. The import of condoms has become cheaper than manufacturing them in India. The GST Council has decided to tax natural rubber at 5% and synthetic rubber at 18%, something the All India Rubber Industries Association has protested saying that this tax burden was higher than what …

Kamasutra condom manufacturer moves HC against govt’s cap on price

The manufacturer of Kamasutra condoms has moved the Delhi high court challenging the government’s decision to cap the price of its range of male contraceptives. A bench of chief justice G Rohini and justice Sangita Dhingra Sehgal is likely to hear the matter on August 12. The company, JK Ansell, has challenged the Centre’s March 2, 2016 order whereby the …

condom manufacturing plant in india

As a manufacturing plant, Triofab (India) Pvt ltd has successfully supplied fully automatic condom manufacturing plants on turnkey basis to Hindustan Latex Ltd & Polar latex Ltd These plants involve sophisticated technology, complex automated controls and machinery which include fully automatic molding machines, manual & automatic vulcanizing machines, pin hole testing machines, latex storage tanks etc. they have commissioned plants having …

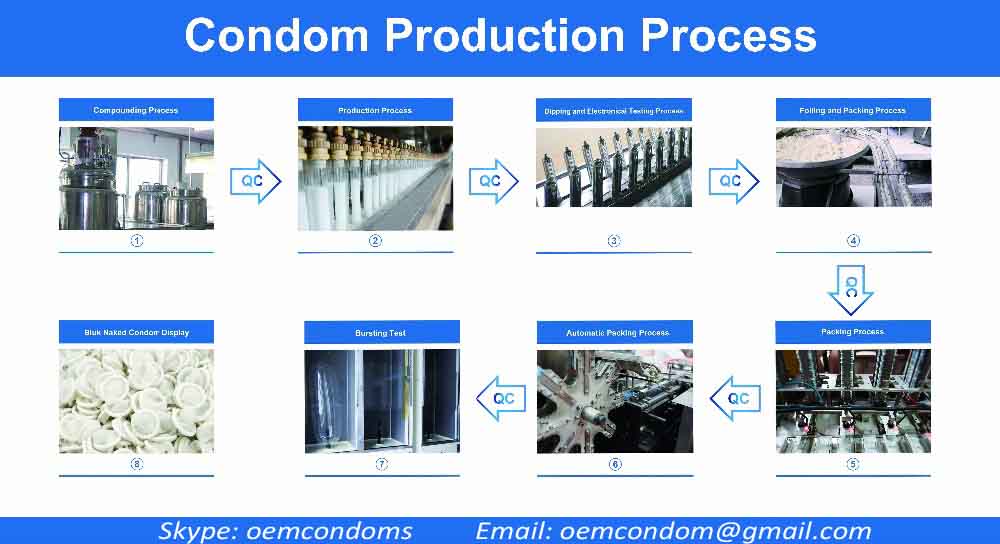

Condom production Moulding Process

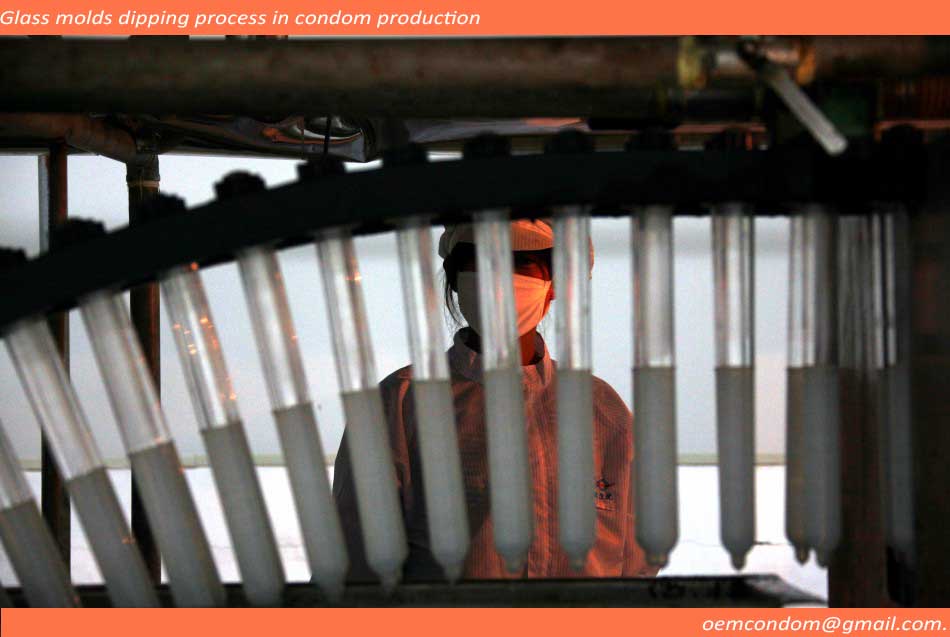

The condom is produced continuously by glass dipping molds install on chain conveyor, which will traverse, up and down, turning the course, on the whole dipping process in a continuous cycle. Glass moulds will be gradually descended and dipped into the dipping tank filled up with the compounded latex. Glass moulds sticked with the compounded latex are then sent to …

Thai Nippon Rubber Industry Co., Ltd

Thai Nippon Rubber Industry Co., Ltd. is part of Charoen Aksorn Group, began its operation in Leamchabang, Chonburi, Thailand at 1993 with installed manufacturing capacity of 75 million pieces per year. At present the manufacturing capacity has increased to 300 million pieces per year. Thai Nippon Rubber Industry Co.,Ltd. is the quality manufacturer of natural rubber latex male condom. They accredited …

Condom Production Vulcanizing Process

The condom is dried and added with silica powder in blender, which automatically tumbles and feeds out condoms in a collection box, then carried to vulcanizer. After vulcanizing and cooling where thoroughly depowdered in each separate process, the vulcanized condoms are randomly sampled for the first visual inspection and physical property testing. The accepted condoms are sent to pinhole testing …

Best condoms of Mango brand

Mango condom® is professional condom manufacturer at China, started from 2008. Germany and Chinese engineers worked together to installed the condom production dipping lines for us, and we also improved little by little to make it more good quality control, together with advanced new equipment of dry method electronically testing line, and all our latex import direct from Thailand’s latex garden plant, which …

Condom expiration dates

What is the condom expiry date? Each condom manufacturer must determine the shelf life for their condoms. Our condoms have a shelf life of 5 years from the date of manufacture. Some condom such as spermicidal lubricated condoms may have a shorter shelf life. Can I use a condom if it has expired? People should always use condoms within the …

your brand condom deserves a quality condom supplier.

we had served more than 50 worldwide condom brands.