Condom making & manufacturing process

Here listed the process how to make a condom plant to make condoms:

Phase 1: up-date of the recent feasibility survey for the selected country/ sitePhase 2: construction of factory buildings, acquisition and installation of machinery and

equipment for quality control, sealing and packaging – start marketing to private brands &

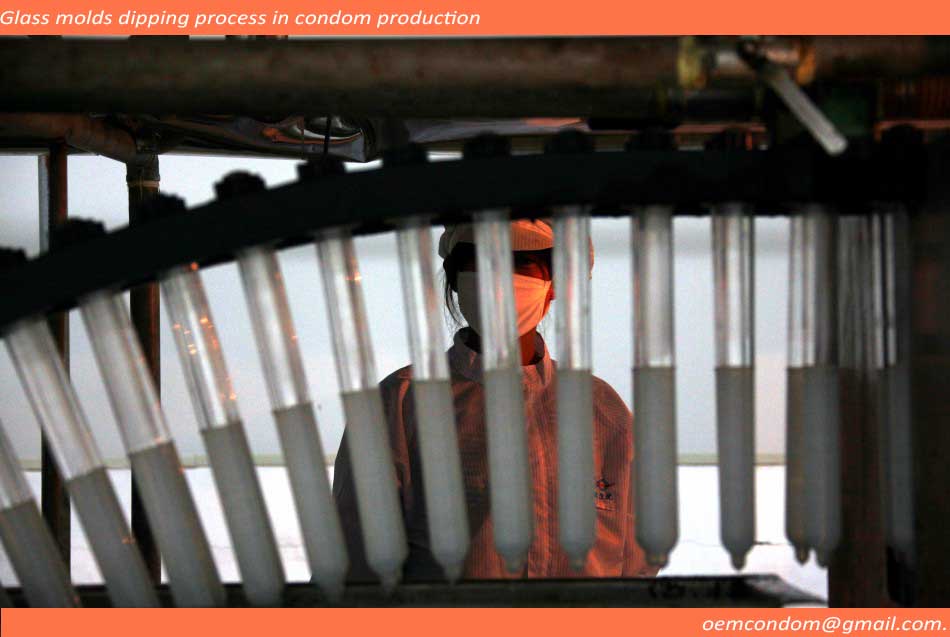

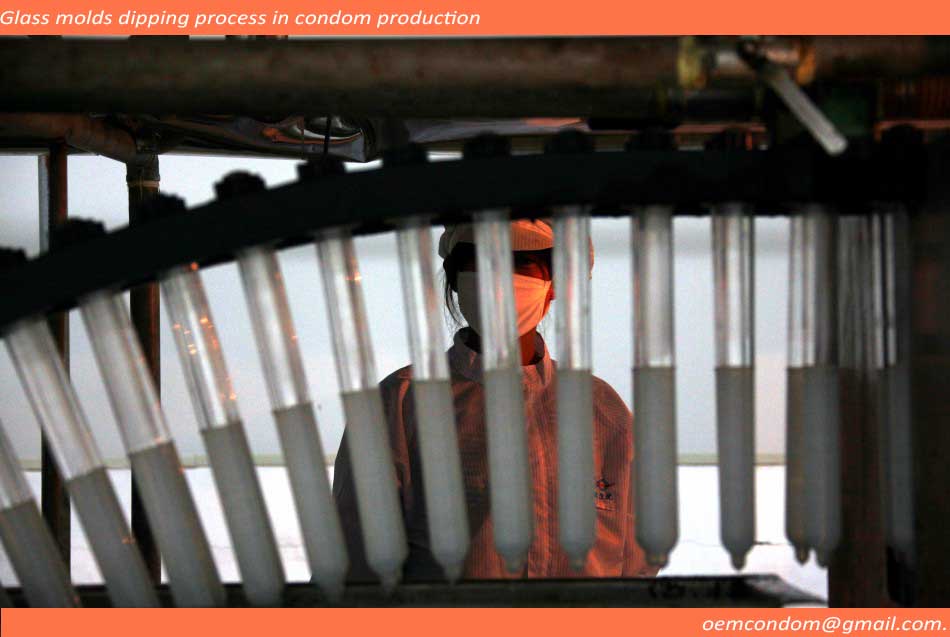

donorsPhase 3: setting up the machinery to produce 120 million condoms (‘dipping lines’) annually.

Total number of lines: four, each producing 30 million condoms.

Advantage of smaller quantity dipping lines: production can easily continue on smaller scale in case of severe power failure or delays in latex supply.

Additional Costs: Purchase of motor vehicles, generator, raw and packaging materials

Provision for pre-operating expenses: training of staff

Working capital to ensure smooth implementation

Energy provision: possibility of solar/wind energy (costly)

We have mature process in our condom manufacturing industry and distribution in china. Our condom is made by WHO ISO4074:2002 GB7544-2009. Main condom ingredient is nature latex and some of them made from polyurethane that design for those who are allergic to latex.

Condom type/size/color can be designed by clients requests, Custom condoms order is possible, welcome contact us by email, we are pleasure to workout for clients own branded condoms:

- Email: sales@oemcondom.com

- OEMcondom@gmail.com

- Whatsapp:+86-13371246800

- Contact: Guo Dong